Walk into any modern factory or lab and you’ll notice something: robots are no longer a futuristic accessory; they’re part of the furniture. What used to be the territory of research prototypes is now the daily reality for production lines, warehouses, and even service industries. This shift didn’t happen overnight. Behind it are specific technologies quietly making robots faster to build, easier to program, and smarter in the way they work.

Here’s a look at seven of them.

1. Advanced Sensors and Vision Systems

A decade ago, robots “saw” the world in blurry outlines. Now, thanks to high-resolution cameras, LiDAR, and depth sensors, they perceive depth, texture, and movement in real time. This isn’t just for obstacle avoidance — it enables precise assembly, quality inspection, and even collaborative work alongside humans without safety cages.

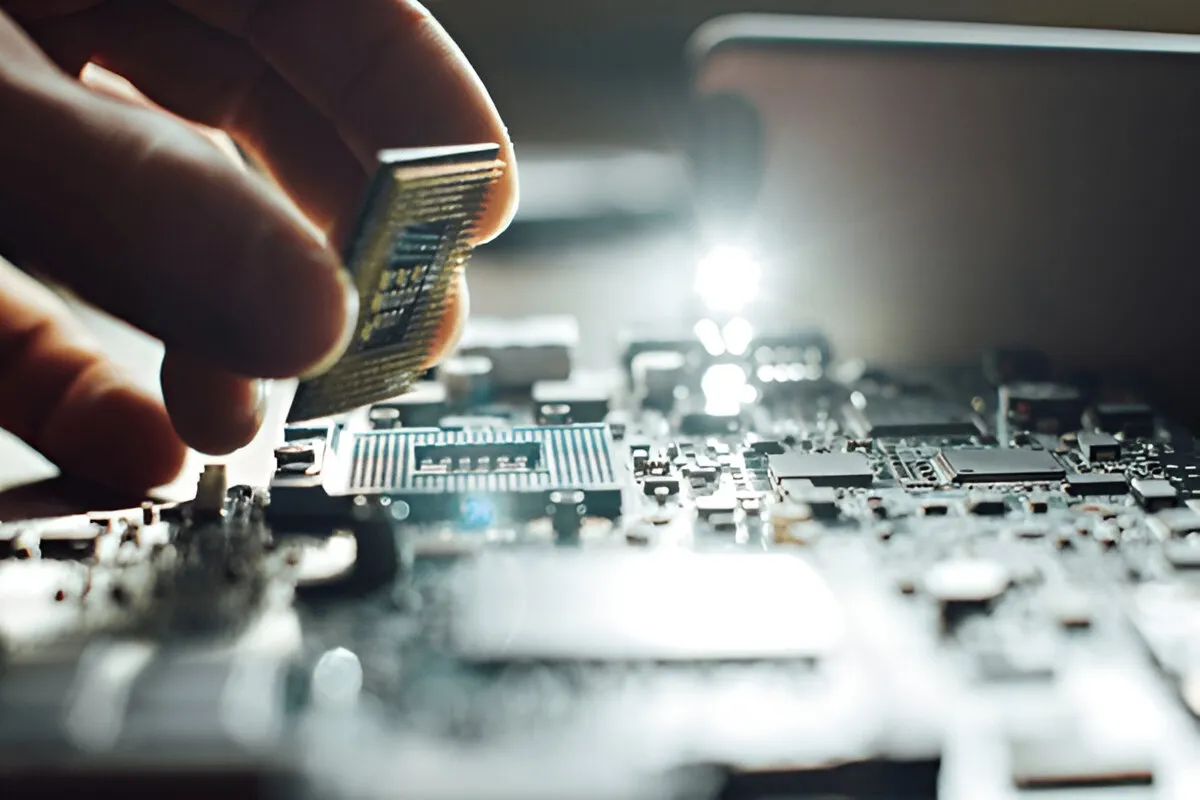

2. AI and Machine Learning at the Edge

Robots used to depend on pre-programmed instructions, making them rigid in unpredictable settings. The integration of compact AI processors means they can process data locally — no cloud round trips needed. Whether it’s a mobile robot navigating a busy warehouse or a surgical arm adjusting to micro-movements, edge AI cuts latency and boosts autonomy.

3. Modular Robotics Platforms

Instead of designing each robot from scratch, engineers now rely on modular kits with interchangeable joints, grippers, and controllers. This slashes development time and cost. A company can build a robot for packaging today and, with a few swapped components, reconfigure it for inspection tomorrow.

4. Digital Twins

Before a single motor turns, a complete virtual copy of the robot and its work environment can be built. Engineers can test scenarios, simulate wear, and predict failures — all without risking downtime. Once considered a luxury for big aerospace projects, digital twins are now accessible to small manufacturers thanks to cheaper computing power.

5. Low-Code and No-Code Programming

Not every robotics engineer is a software specialist, and that’s fine now. Drag-and-drop interfaces and graphical workflows let operators program complex movements without typing a single line of code. This democratizes robotics, allowing smaller businesses to adopt automation without building large engineering teams.

6. High-Efficiency Batteries and Wireless Charging

Mobile robots can only be as useful as their power source allows. Recent improvements in battery density and charging methods mean autonomous guided vehicles (AGVs) can work longer shifts and “refuel” in minutes. Inductive charging pads even let them top up during brief idle moments.

7. Collaborative Safety Systems

Robots that can safely share space with humans are a big deal. Modern safety sensors, force-limiting joints, and AI-driven hazard detection mean that collaborative robots — or “cobots” — can work right at the same bench as people. This flexibility removes the need for large safety enclosures and opens automation to smaller floor plans.

The Bigger Picture

The interesting thing about these technologies is that none of them alone is enough to spark a robotics boom. The real acceleration comes from how they intersect. A modular robot with advanced vision, running on edge AI, can be deployed in days, not months. Add digital twin testing and you cut the risk before it even starts working. Wrap it all in a no-code interface and suddenly you don’t need a PhD to operate it.

This is why we’re seeing robotics adoption move beyond automotive giants and into mid-sized manufacturing, logistics, agriculture, and even healthcare. The barrier to entry is shrinking, both in terms of money and skill requirements — including access to qualified instruction. A growing number of specialists now teach robotics and automation remotely, with platforms such as this one offering lessons and classes for different levels of experience.

Robotics isn’t just replacing repetitive labor — it’s expanding what’s possible. A small farm can now afford autonomous harvesters. A regional hospital can run precise robotic-assisted surgeries without a full-time robotics engineer on staff. What once took years to implement can now be done in a fraction of the time.

And that’s the real story: speed not for its own sake, but speed that comes from precision, adaptability, and smart tools. The future isn’t just about more robots — it’s about robots that arrive ready to work from day one.